Making Electric Vehicle Creation Sustainable

Table of contents

The discussion covers a broad array of topics, from differing business attitudes to sustainable product development, and generational changes in customer requirements; to the importance of dynamic new market entries such as the Lightyear 0.

Henk began his career as a Chemistry and Physics teacher before becoming heavily involved in environmental health and safety, energy, and sustainable development at the global electronics conglomerate, Philips.

In this interview, Henk details his unique perspective: having spent much of his career working for a global conglomerate, how he came to work with Lightyear at the helm of their sustainability agenda, and where he sees this innovative company – and the automotive industries as a whole – heading in the next five years.

What Does Corporate Sustainability Mean?

Henk’s experience in corporate sustainability spans over 30 years, with the last 4 spent at Lightyear.

“So, I retired at Philips, and then I said, okay, maybe it’s good that I can use my experience to help [Lightyear] to really become sustainable, because that’s a little bit more than just CO2 reductions.”

As Henk explains, the umbrella term “sustainability” has come to refer to many different aspects of a company’s operations. Nowadays, sustainability covers environmental, social, and governance objectives.

Retaining Stakeholder Investment in Sustainable Goals

It’s true that a lot has changed since 1988 – when Henk first became involved in environmental health and safety – but all that experience has taught him a lot about bargaining for stakeholder investment in sustainable development goals.

“If you take a look at it from a business perspective, maybe you can do things differently. And that stance I’ve always taken. And so that’s my personal point of view. How can you use sustainability as a business driver?”

In fact, this approach is valid regardless of the organization you apply it to. Whether you’re a multinational enterprise, an established SME, or a startup. Whether you’re in high-tech, construction, automotive, or life sciences. Tackling sustainable goals by promoting business drivers is the most effective method of forging a path forward.

“If you’re in the short-cycle products like food or textiles, the story will be a little different. But from a strategic business perspective – particularly for the high-tech industry – I think it can be very interesting to use it as a business driver.”

Henk posits that it’s best to put cost benefits first when pitching a sustainable startup. It’s a straightforward business thought that a surprising number of startups fail to check. Thankfully, though, the numbers are more often on the side of sustainable businesses than they aren’t.

How is the Automotive Industry Business Model Changing?

The cost benefits of efficient waste management are practically self-evident in most organizations. But another simple rule of thumb that Henk outlines is the mandate to use as many recycled materials as possible. This can be exceedingly effective in reducing carbon emissions. Finally, and perhaps most poignantly, organizations should start design development with the intention of creating a product that will last forever.

“And if it does not last forever, it should be easily repairable. The parts that you choose should be reusable and the materials that you choose to make the parts should be recyclable, as much as possible. And that’s called circular thinking.”

This simple principle – at least on first hearing – sounds to be by far the most disruptive piece of guidance from the Lightyear VP of Sustainability. Surprisingly, however, it’s not an entirely new business principle.

“If a big airliner is purchasing new airplanes, the engines usually are from Brett and Whitney, or from Rolls Royce or whatever. So, if you buy a new aircraft, the engines are just in a business model that is guaranteed forever that it will work, and you pay an X amount either in a lease or a rent.”

In this business model, the parts come with a lifetime guarantee and a leasing or service agreement. This is some way toward the circular thinking that Lightyear are talking about in relation to their first fully commercial release.

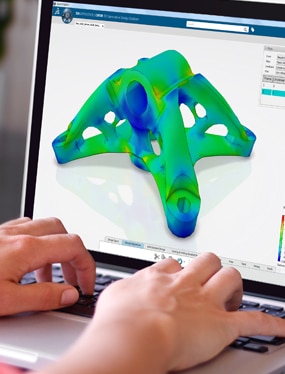

They’re talking about putting new cars into the market that are reusable or recyclable within a 10–15-year lifecycle. To do this, they’re using the 3DEXPERIENCE platform to help manage the entire product lifecycle, and particularly with the careful consideration of material usage in the very early design phases.

“Let me put it this way. Most development processes are linear. Meaning that you have an idea. You put things together and then ultimately you think that it lasts for a certain amount of time, and that’s about it. And if you start thinking in a circular way, it simply means that you need to do some redesigning. But it’s not really rocket science what you need to do differently.”

New Technologies that will Play a Part in the Future of Automotive

All this redesigning of products, services, and business models will ultimately have a profound effect on the market and on end user experiences. As in many industries, beginning largely with software, automotive is moving toward the “as-a-service” model. This is a tremendous break with tradition in terms of market mentality.

However, Henk states that – in his view – there’s another new technology that will be instrumental in crystallizing this shift.

“If autonomous driving becomes more evident and more practical – to a certain extent – the whole business model world and the whole world will completely change. Then it becomes a service.”

This is where PLM and virtual twin technologies really come into their own. When a product and service are combined in the consumer offering, it’s vitally important for the manufacturer to have real-time insight into design, production, and aftermarket data. Henk mentions that it’s crucial for the CEO and the Board of Directors to have access to a “cockpit with five screens” to give snapshot reporting on financial, social, environmental parameters, and more.

“There will be interlinks to see, hey, sometimes you see a financial parameter changing and that can be a correlation with other parameters.”

By taking this approach, a company can start to make decisions based on the clear and provable correlations between financial performance and social or environmental factors. At that point, you can really say that you’re taking the full picture into account. So that it’s no longer just about the product, but also about the processes, the usage, the full lifecycle.

Why Design Electric Vehicles with Sustainability in Mind?

In summary, Henk describes the main benefits of Lightyear having started out with sustainability at the forefront of their product design aspirations.

“The main benefits will be that in the total segmentation of customers, you will attract two categories that are relevant. One is the people that are more interested in the green part, but the second one will be interested in the cost savings because the car is so extremely efficient.”

But Lightyear are also interested in the opportunities that circular business presents.

“We, of course, we did already some calculations in extrapolation over the 10–12 years. You can really have an interesting profit and increase your turnover by simply starting to accommodate the [service] market.”

And in closing, Henk reflects on the early 2000s, when most people predicted a slow development on the electric vehicle marketplace. Here, however, he alludes to the dramatic effect that autonomous driving could have on the entire automotive industry.

“People were convinced that EV development wouldn’t go that fast. Now it’s going very fast. I think autonomous driving and total cost of ownership models and so on will also go at the same pace. So, if you don’t start thinking and incorporating it into your thinking now – as a new startup company – you’re gone. And by the way, just see what happens with the traditional OEM set.”

In Our Experience…

In 2019, we described Lightyear’s goal to be a “catalyst to the sustainable market transformation”. Today, Lightyear continues to show a resolute focus on those values, backed by a rich understanding of the business drivers that are fueling this transformation.

Businesses – like Lightyear – that are making that enormous step in the right direction, are often doing it because they want to be better. And most CEOs today see sustainability as central to an effective company strategy. But it’s crucial now that all companies can easily report on real-time data that supplies reliable insight into correlations between economic, social, and environmental factors throughout a product’s lifecycle.

Discover the best, flexible software, tools, and services to support your startup during this crucial initial growth period and beyond.