What is Cradle-to-Cradle Product Development?

But industries also need to focus on economic and energy-efficient production. For one thing, we must meet all kinds of environmental requirements and minimize the use of harmful materials.

Raw materials are increasingly scarce and while pollution is down, it still occurs. In fact, pollution has merely slowed down. Recovery of materials by means of recycling alone is not the answer either. Recycling PET plastics to manufacture clothing, for example, produces a lower grade plastic than the original material. This is also referred to as downcycling.

Moreover, the fibres contain toxins such as antimony, ultraviolet stabilizers, plasticizers and antioxidants. And these synthetic fibres eventually end up in our environment when the clothes are laundered. Therefore, the cycle is still cradle to grave.

The Cradle-to-Cradle Philosophy

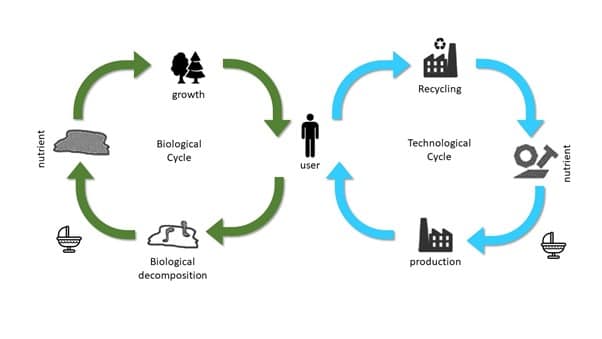

Cradle-to-cradle is a design philosophy developed by Michael Braungart and William McDonough They introduced in their book Cradle to Cradle — Remaking the Way We Make Things. This philosophy promotes that raw materials are not wasted, but retained within the biological or technological cycle. Waste is a nutrient, either for the biosphere, or for the technosphere. It is therefore important to reuse these raw materials, either as fully compostable biological material, or as high-end technological resources. Every product is part of a perpetual cycle, in which it is reused and preserves or increases its value. Upcycling instead of downcycling. Now the cycle goes from cradle to cradle.

Products designed according to the cradle to cradle philosophy do not contain any harmful substances. The raw materials used in the production process meet the same requirements as the raw materials that were originally extracted. The required energy is produced sustainably. Packaging materials have value: biological material like rice hulls, for example, are a waste product of rice production. They can be used as packaging material and subsequently reused or serve as nutrients for the biological cycle.

Biodiversity, conceptual diversity and cultural diversity are encouraged. This results in robust processes and products, creativity and effectiveness.

Fairness and Economic Aspects

Cradle to cradle also stands out by its evaluation of designs against principles of fairness and economy.

Fairness ensures that everything within an ecosystem is treated with respect. Production is never at the expense of human or animal rights. Employees work in a clean, healthy and natural environment, are not exposed to harmful substances – which, after all, are not being used – and receive a decent pay.

If the cradle-to-cradle philosophy is to succeed, the aspects of ecology and fairness must be feasible and economically viable. Therefore, cost-effectiveness, competitiveness and profitability are important prerequisites for success. A product can be seen as a service, with raw materials remaining the property of the manufacturer. The user is therefore not charged for them, and the manufacturer does not lose the valuable raw materials. Given that a cradle to cradle factory does not pollute, it doesn’t need to finance expensive solutions to reduce or filter emissions. Waste water is clean and does not contain any harmful substances.

A product is considered cradle-to-cradle only when it is fully reusable and does not produce any landfill waste, while still being competitive and profitable. This all needs to be achieved through a fair production process.

In Our Experience…

It takes quite a lot to put cradle to cradle into practice. First you have to carefully consider the materials in use. Are they responsibly-sourced, harmless for the users and the result of a non-toxic manufacturing process?

Following this, the tracking and collecting of product materials after usage, recycling and reuse entails quite a logistical challenge. Additionally, investments are required for production facilities, training and product development.

By establishing synergy between environmental, economic and fairness aspects, great results can be achieved. These can include combating global warming and pollution of the biosphere, and promoting ecological and cultural diversity. Not to mention the prospect of biological, technological and prosperity growth.

If you want to know more about the tools that can be used, and technical aspects of implementing a cradle-to-cradle Product Lifecycle Management (PLM) strategy, check out our blog on, “What is PLM?“

From Design Engineering to Manufacturing and Aftercare…

Discover the ways in which 3DEXPERIENCE can guide your approach to sustainable product creation