Why is PLM Important When Creating a Circular Economy?

Table of contents

In a circular economy, the focus is on designing products that are made from renewable and biodegradable materials, which are energy-efficient and that can be easily disassembled and reassembled. The idea is that products should be designed with the entire lifecycle in mind, from sourcing of materials, production, use, and repurposing.

In this new economy, the traditional “end-of-life” stage in the product lifecycle is really the primary focus. During this phase, waste materials are collected and used as inputs for new products, rather than being sent to landfills. This can be achieved through recycling, composting, and other forms of resource recovery.

In terms of sustainable product design and manufacture, this means designing products that can be easily repaired, reused, refurbished, or recycled, rather than designing them for disposal after a single use.

Overall, circular economy is a holistic approach to sustainable product design and manufacture that aims to keep resources in use for as long as possible, minimizing waste and pollution, and creating a more sustainable system of production and consumption.

Business Opportunities Within a Circular Economy

Opportunities that can be recognized by businesses if a fully circular product development strategy is applied, include:

1. Cost savings: Circular economy strategies can help reduce the use of new resources and minimize waste, which can lead to cost savings for businesses. For example, using recycled materials in product development can be less expensive than using new materials, and closed-loop manufacturing can help reduce waste and save on raw materials.

2. New revenue streams: The implementation of circular economy strategies can also create new revenue streams for businesses. For example, companies can generate revenue by selling recycled materials or by offering product-service systems, such as leasing or renting products. Upcycling can also create new business opportunities.

3. Increased brand value: Companies that adopt circular economy strategies can differentiate themselves in the market and increase their brand value. As consumers become more conscious of environmental issues, companies that can demonstrate their commitment to sustainability and circularity can be more attractive.

4. Innovation and new product development: Implementing circular economy strategies can drive innovation and lead to the development of new products. For example, by designing for disassembly and recyclability, companies can create new opportunities for modular and standardized products. This can also open opportunities for upcycling or creating new products from waste material.

5. Increased efficiency: Closed-loop manufacturing and other circular economy strategies can help companies to increase efficiency in their production processes, as well as reducing their environmental impact.

6. Regulatory compliance: As regulations related to circular economy become stricter, companies that adopt these strategies will be well-positioned to comply with regulations, avoiding potential penalties and fines.

7. Collaboration: implementing circular economy strategies often requires collaboration with suppliers, customers, and other stakeholders. This can lead to new business opportunities by creating new partnerships and networking opportunities. The PLM Green Global Alliance (PGGA) is an international community of professionals who work with Product Lifecycle Management (PLM) enabling technologies and who are collaborating for a more sustainable decarbonized circular economy.

All these business opportunities can lead to long-term sustainable success for companies and help them contribute to a more circular economy. Implementing a fully circular product development strategy will not only create a positive impact on the environment, but also bring economic benefits to the business.

Circular Economy and Product Lifecycle Management

There are several strategies, supported by Product Lifecycle Management (PLM), that companies can pursue in product development to start creating a circular economy. Some of these include:

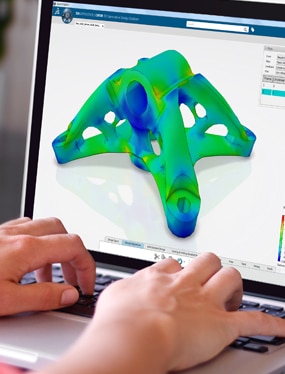

1. Design for disassembly and recyclability: This approach involves designing products in such a way that they can be easily disassembled, and the materials used in them can be easily separated and recycled. This can be achieved by using modular design, standardized components, and designing products that can be easily opened and repaired. PLM systems store information on the design of a product, including the materials and components used, as well as assembly instructions. This information can be used to ensure that products are designed for disassembly and recyclability and can help identify opportunities for modular design and standardized components.

2. Use of recycled materials: Using recycled materials in product development can help reduce the use of new resources and minimize waste. This can include using recycled plastic, metal, glass, and other materials in the production of new products. PLM makes it possible to track the use of recycled materials throughout the product development process. This helps to ensure that products are made using sustainable materials and can also help identify opportunities to reduce the use of new resources.

3. Product-service systems: Instead of selling a product, a company can sell access to the product or the service that it provides. For example, rather than selling a drill, a company could sell access to drilling services. This can lead to more sustainable use of resources and a shift from selling products to selling services. PLM systems can be used to manage the entire lifecycle of a product, including its design, development, and end-of-life. This helps companies move away from a product-focused model to a service-focused model and make more informed decisions about the products and services they offer.

4. Lease or Rent: A company can allow customers to rent or lease their products, instead of selling it. This way the company remains in control of the product, allowing proper disposal or refurbishing at the end of the lease period. PLM can be used to track the use of leased products.

5. Closed-loop manufacturing: This approach involves designing products and manufacturing processes that can be easily adapted to recycling and repurposing. This can include using closed-loop manufacturing processes, where waste materials are recycled and reused in the manufacturing process. PLM can be used to track the use of materials and resources throughout the product development and manufacturing process, which can help identify opportunities for closed-loop manufacturing.

In Our Experience…

By leveraging PLM, companies can design products with disassembly and recyclability in mind to start creating a circular economy. The system helps ensure that products are easily disassembled, and their materials can be separated and recycled effectively. Additionally, PLM helps you to identify suitable recycled/recyclable materials, enabling your organization to reduce the consumption of new resources and minimize waste.

PLM also supports the transition from a product-focused model to a service-focused model. By doing this, your company can offer access to products or services instead of selling physical products, contributing to a more sustainable use of resources. Overall, PLM enables informed decision-making about the products and services you offer.

Implementing a fully circular product development strategy supported by PLM not only benefits the environment, but also offers significant economic advantages for businesses. Companies can realize cost savings, explore new revenue streams, increase brand value, foster innovation and new product development, improve efficiency, ensure regulatory compliance, and foster collaboration with stakeholders.

So, let’s start paving the way for long-term, sustainable success while simultaneously contributing to a more environmentally conscious and economically viable future. Together, we can start Making Product Creation Sustainable.