Simulating Geomechanics and Fracking with Abaqus

I remember how business was back in 2009. Global recession was biting and affecting everyone. It seemed that everyone had stopped buying new cars, and that most people had chosen to avoid flying, where possible, so both the auto and aero markets were in disarray.

The car manufacturers were desperate to sell to anyone, since seemingly most people had chosen to stick with the car they already had, or only replace it with a 2nd hand car. They cut costs by choosing to run fewer physical tests and were compensating by running more simulations of greater complexity.

The major airframe companies didn’t have such healthy order books as they had had before, as airlines decided that they really didn’t need more planes. The sector was also in the middle of getting to grips with defining and establishing new design and simulation methods associated with replacing their metallic materials with composites.

One industrial sector that seemed somewhat immune, was energy. Sure, the price of oil had fluctuated between $147 and $47, so various exploration projects got frozen, but the basic demand for energy was still largely there.

- How difficult would it be to choose to not use any electricity today?

- How about having to go without using your car for a whole week?

- What about turning off your central heating in the middle of winter?

I had this last situation forced upon me a few years ago by the boiler breaking on Christmas Eve. It was quite an eye-opener. I found new levels of respect for previous generations that had no central heating.

So while the price of oil is now back down near $50 again, our basic need for energy continues. A while ago it was pointed out to me that the price of most things is roughly proportional to the amount of energy that they contain, or that was consumed during their production.

Until we do a better job of harnessing the sun, wind, waves, tides, uranium, thorium & deuterium, we are still going to be heavily reliant on fossil fuels to fulfill mankind’s insatiable appetite for energy. As many countries develop and their populations aspire to a higher standard of living, this problem is just aggravated.

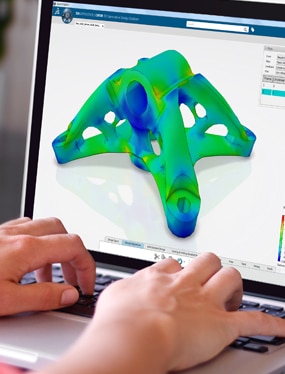

Recent years have seen the rise of “fracking” – as companies use hydraulic fracture methods to split open shale geology and release the natural gas that they have trapped. This technique remains highly controversial and is clearly not yet the perfect solution that some would have us believe it is. I believe that the answer lies in doing our best to fully understand the situation, and proceeding with informed, but confident caution. Building some carefully validated finite element models to explore multiple eventualities is an important part of this process, but up until recently, this has been extremely difficult.

At the SIMULIA Community Conference (SCC) in May 2014, ExxonMobil presented a paper on this topic entitled: “Development and Validation of Fully-Coupled Hydraulic Fracturing Simulation Capabilities”. This paper included details of how they have worked with SIMULIA R&D and Abaqus to use the XFEM capability to model & simulate the required crack behavior.

As we continue to drain the world’s crude oil reservoirs, there is an obvious desire to get the most from these resources. The successful approach taken by many is to build detailed FEA models in Abaqus that couple the reservoir’s flows with structural, thermal and pore pressure effects.